Organic waste gas treatment turned out to be so important

In recent years, the use of organic solvents has increased. We all know that the exhaust gas of organic solvents is volatile, which will always pollute the surrounding air during production and later use. In recent years, the treatment of organic waste gas has been strengthened, and the regulations on the limit value of volatile organic waste gas substances have been obviously stricter. When measuring exhaust gas, the limit values stipulated by the regulator must be followed. The limit values for the concentration of organic waste gas treatment have all been reduced, and some substances, such as dichloromethane, have been reclassified. The general rule for the content of organic waste gas in exhaust gas is that the concentration cannot exceed 50 mg carbon/m3, or the material flow rate cannot exceed 0.5 kg carbon/h. Many production companies must make new investments in the environmental protection of exhaust gas purification.

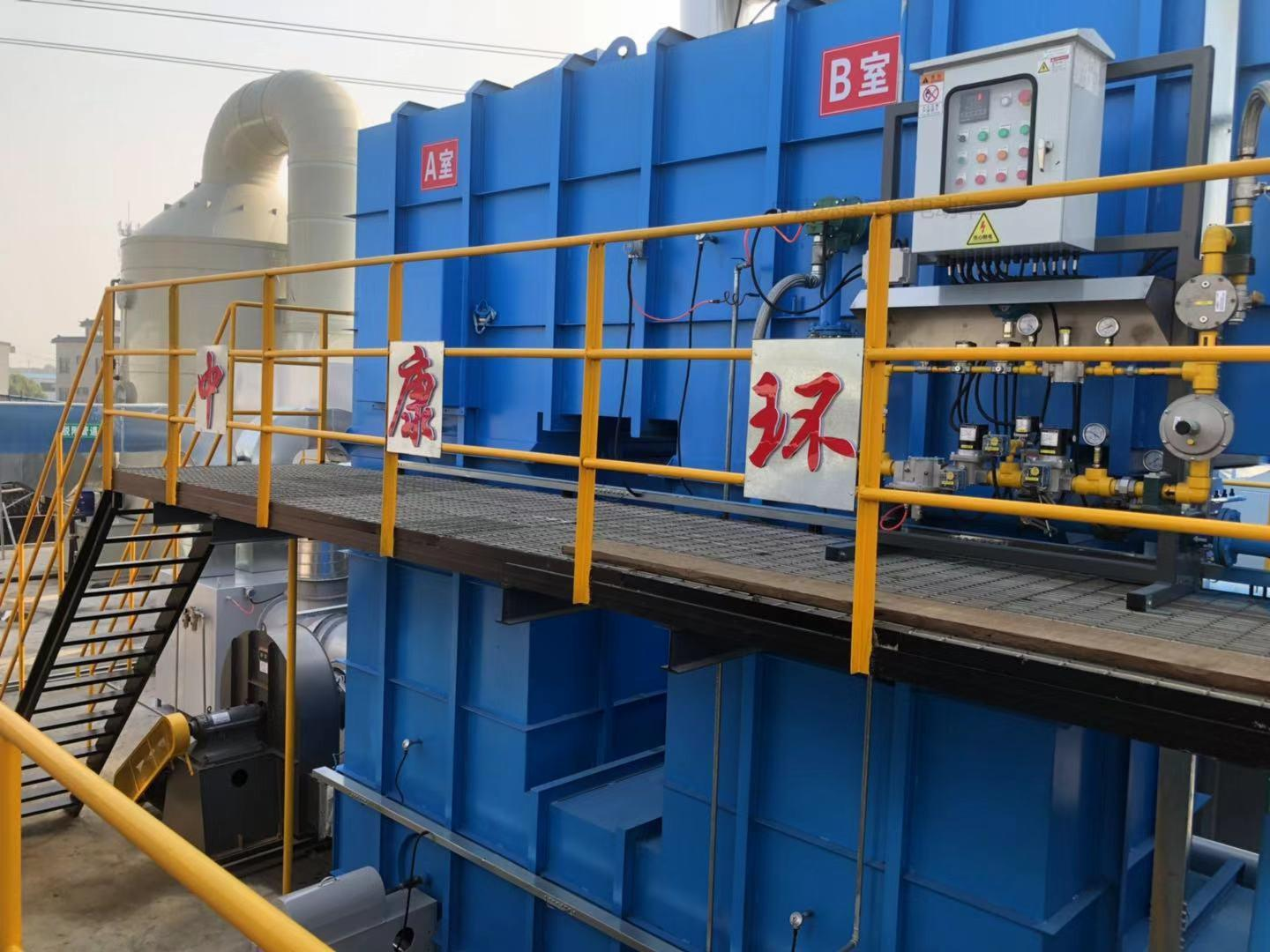

Waste gas treatment equipment

For users and producers of organic solvents, of course, it is proposed to find a suitable process method that can treat organic waste gas to the required value. You must first decide whether you need to recycle organic solvents. In this regard, economic considerations will be used as the basis to consider many factors such as the value of the organic solvent, the concentration of the organic solvent, the volume flow rate of the exhaust gas, and the treatment cost of the mixture that may occur under certain circumstances.

For companies that only use toluene, making organic waste gas treatment decisions is a simple matter. In this case, the cost of the recovery device can be quickly repaid. Although in principle other suitable recovery process methods can be considered, such as condensation, absorption or membrane methods, the gas phase chemical reaction of plant liquids has been considered as a more economical and safe method in recent years.